Introduction

LOBEV pumps for a delicate product transfer

A unique technology, able to adapt to the diverse phases of production processes, always preserving the integrity of products

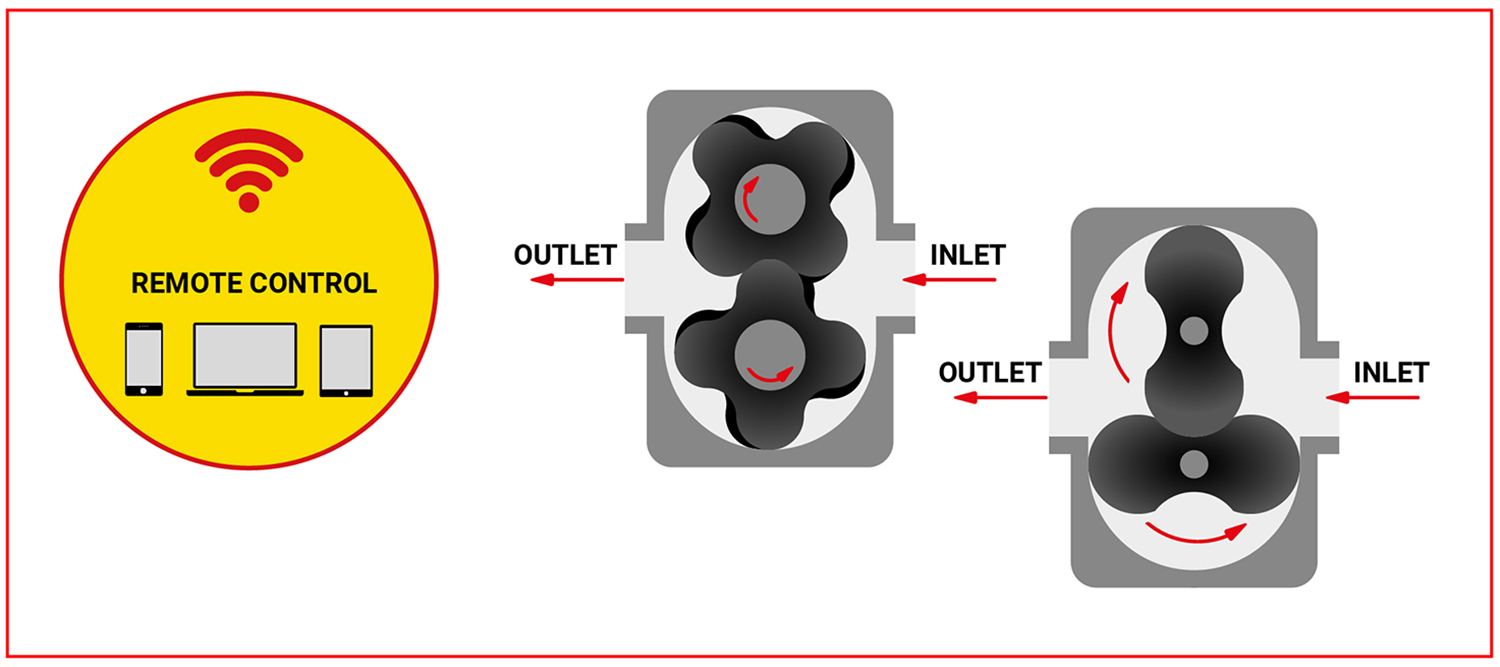

LOBEV pumps, are equipped with two lobe rotors that rotate synchronously on two parallel axes. During rotation, the lobes move the fluid from the inlet to the outlet, creating a continuous flow.

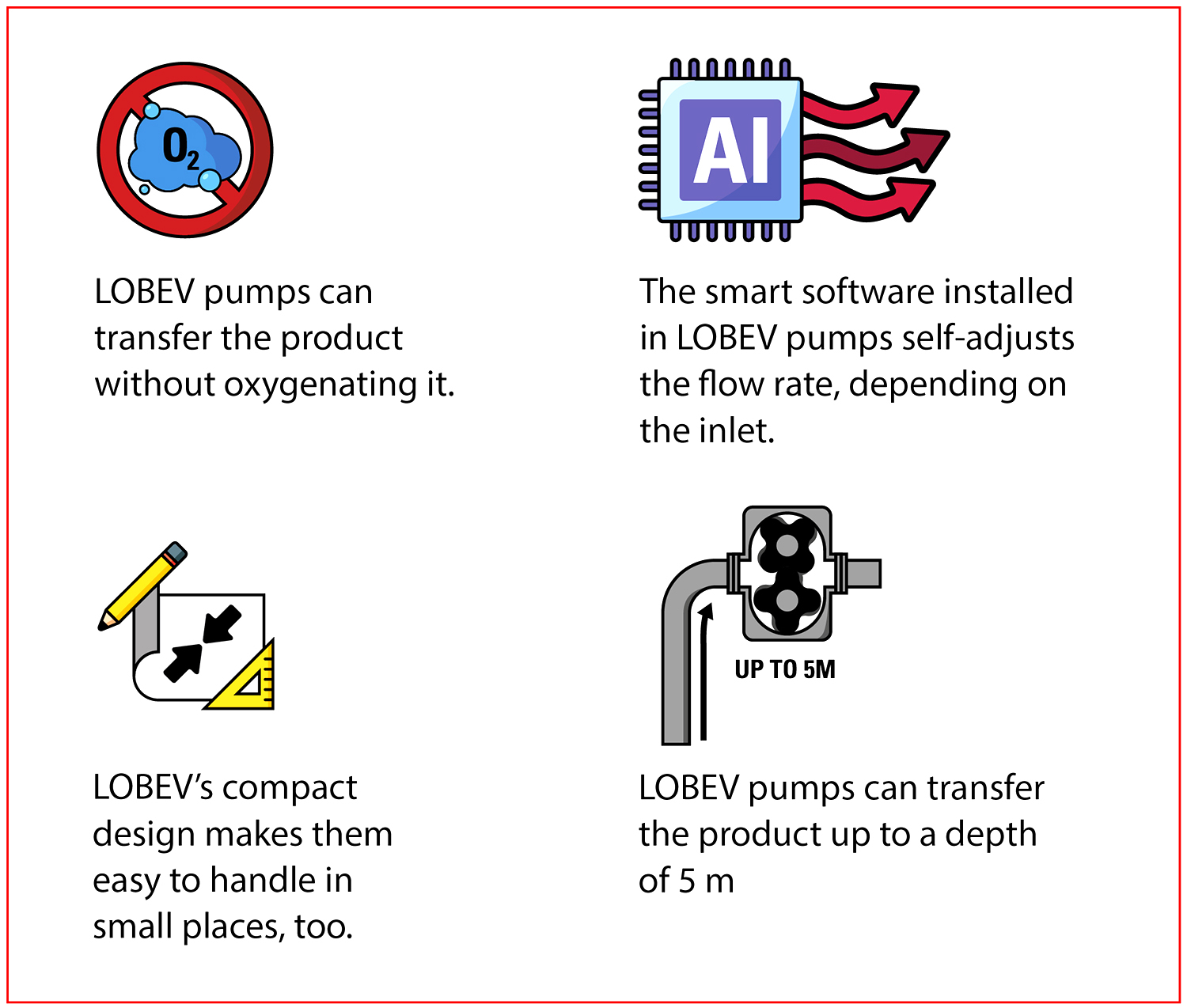

This technology allows to transfer the product delicately, without altering its organoleptic characteristics.

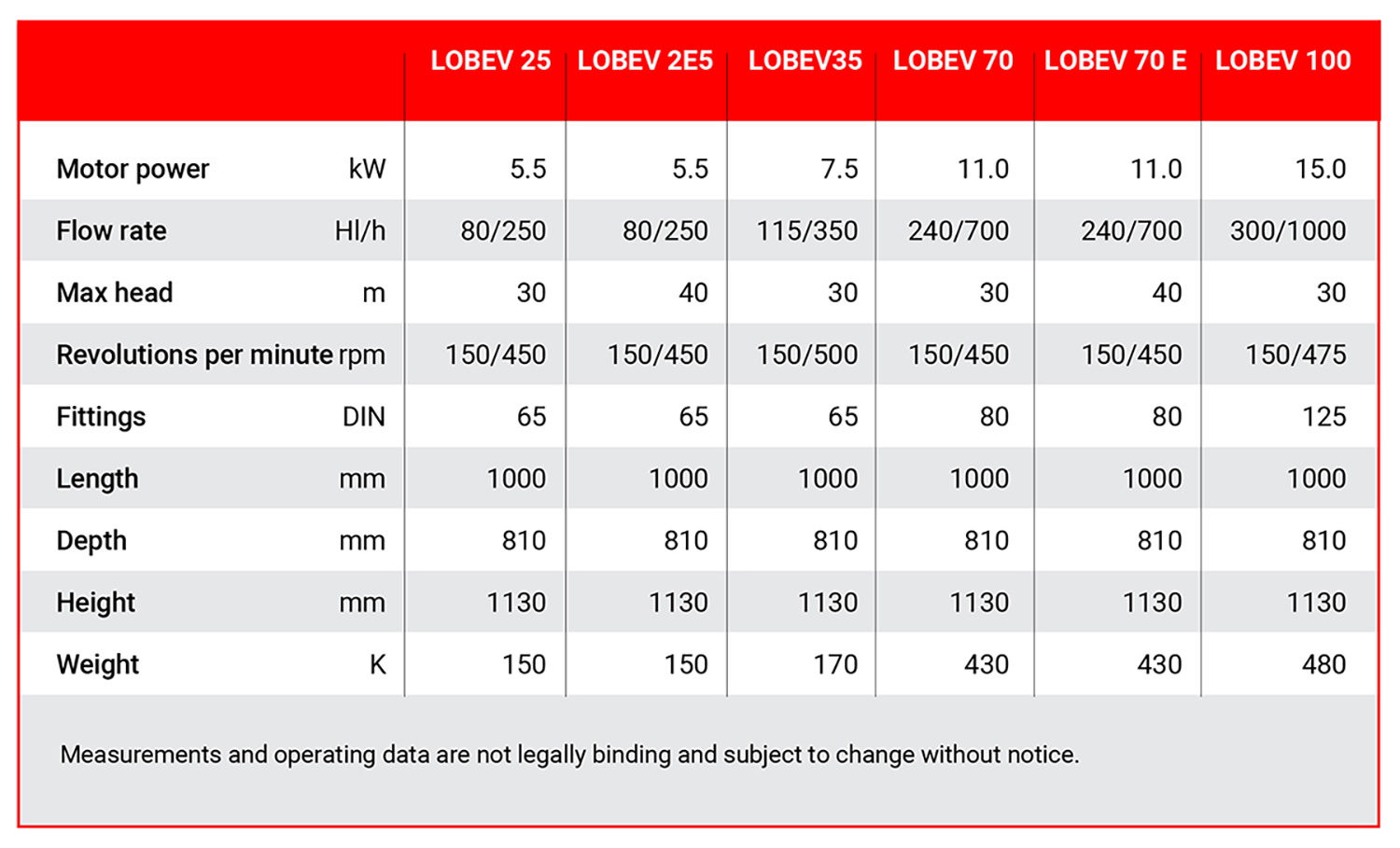

LOBEV pumps are available with standard or helical lobes with hourly flow rates ranging from 80 to 1000 hl.

LOBEV SERIES

Touch screen features

-

The PLC allows the setting of the outlet pressure and its automatic checking

-

Self-learning feature for the flow adjustment depending on inlet

-

Possiblity to set the amount of product to be poured (’Batch’ mode)

-

Inlet/Outlet pressure indicator

-

Arrangement for functioning on bottling lines: automatic flow adjustment depending on analog signal of the line

-

‘Industry 4.0’ ready

-

Standard features

-

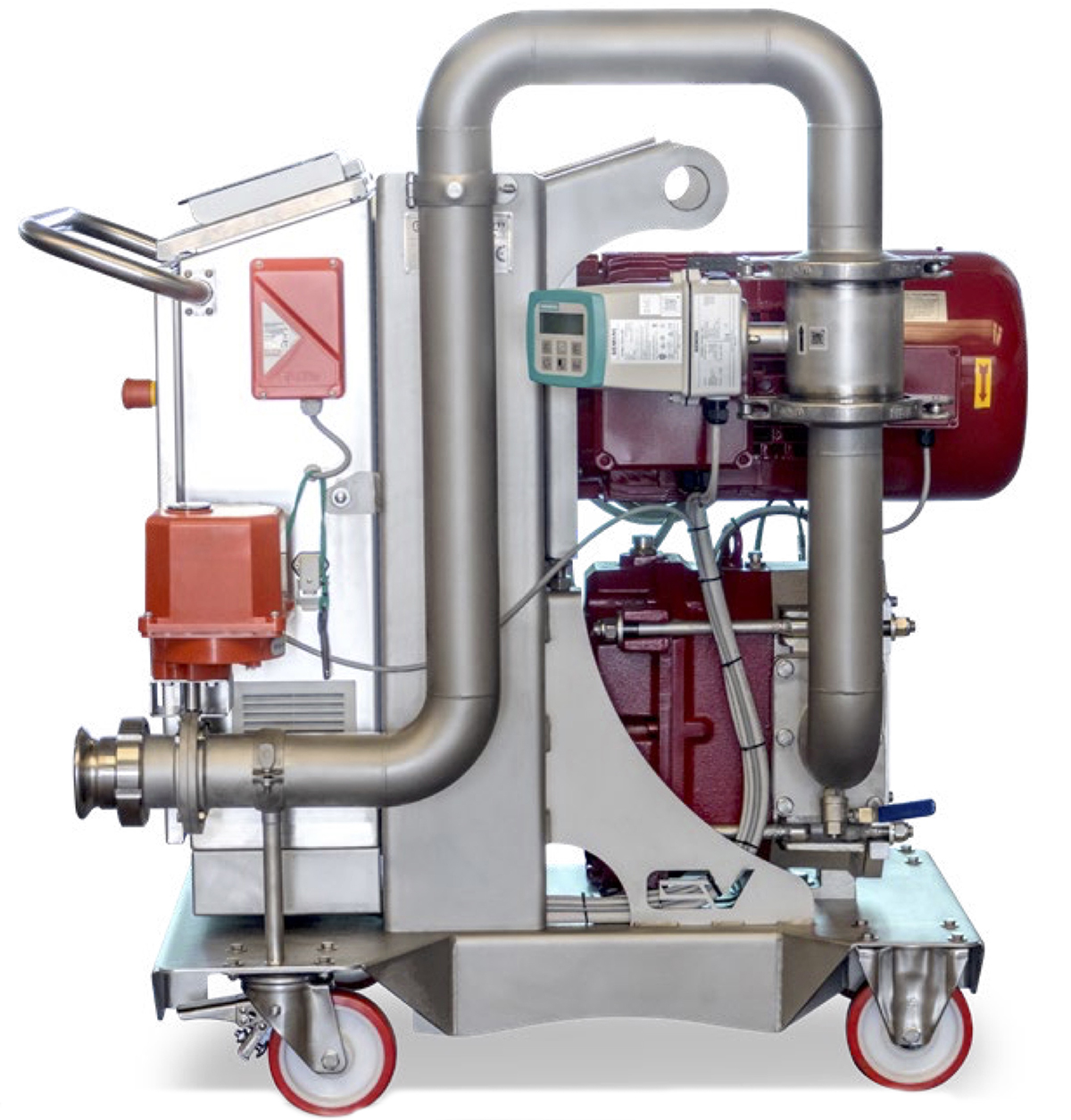

AISI 304 stainless steel stand

-

AISI 316 stainless steel pump body

-

AISI 316 stainless steel lobes, standard or helicoidal (’E’ models), rubber coated, for food use

-

Electronic speed variator

-

7” touch screen

-

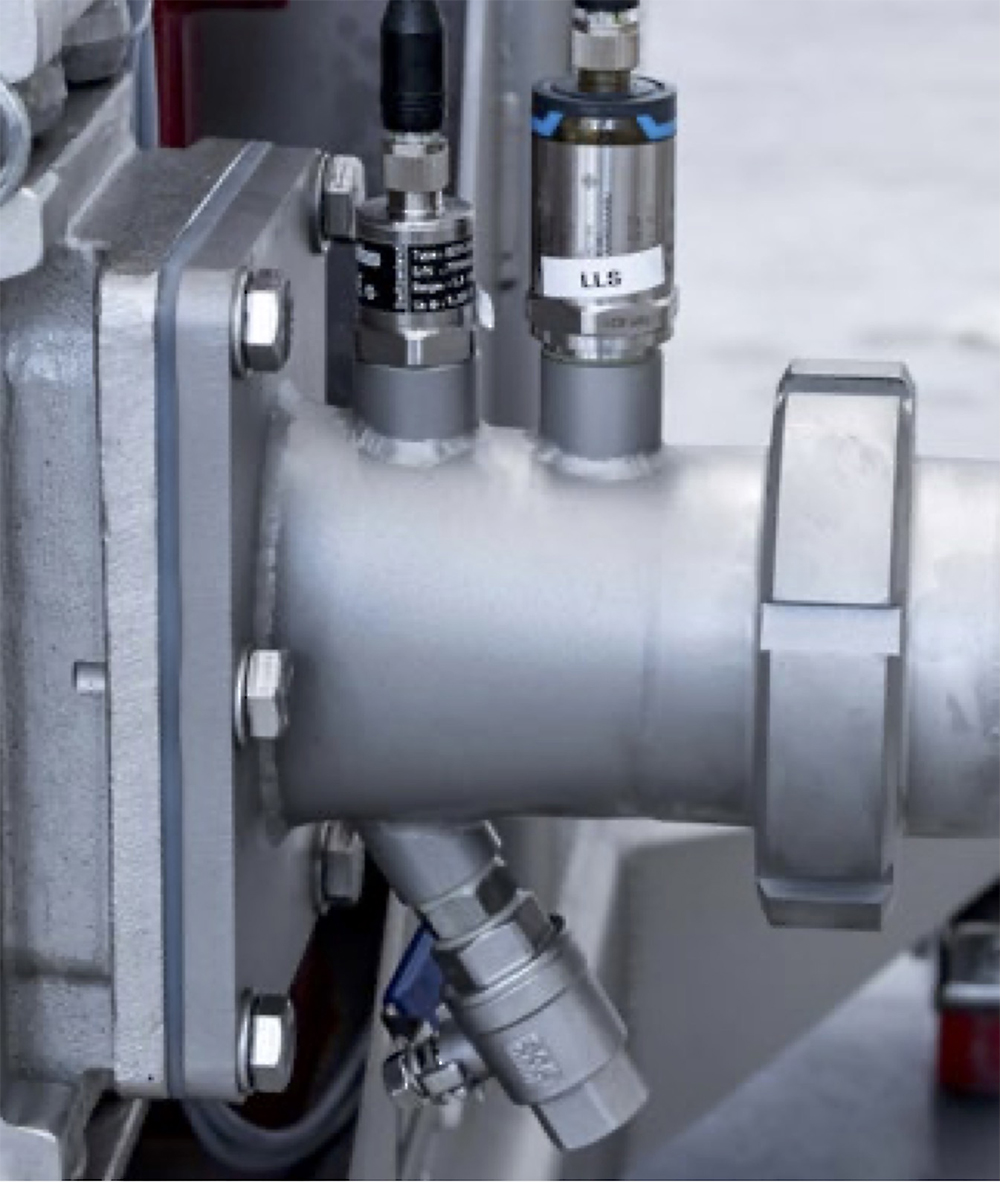

Liquid detection probe

-

Pressure transducer

Optionals

-

Remore radio control

-

Electromagnetic litres counter

-

Enzymes dosing pump

-

Servoventilated motor

-

UV protection for touch screen

-

Nr. 2 membrane expansion vessels

-

Remote control from smartphone, tablet or PC

-

Automatic delivery closing butterfly valve